usp hardness test|tablet hardness tester price : manufacturer One commonly employed test of the ability of tablets to withstand mechanical . WEB11 linhas · 19 de ago. de 2020 · Lotofácil. Últimos resultados. Resultado 2015 da .

{plog:ftitle_list}

13 de ago. de 2013 · Minha impressora hp deskjet 3050 não tira xerox, não sei por que? Troquei o cartucho preto e quando fiz a reposição ela não quer tirar mais xerox, diz sempre no visor dela" instalação", mas eu não entendo porque essa mensagem, já que eu fiz a instalação direito e antes de trocar o cartucho ela tirav.

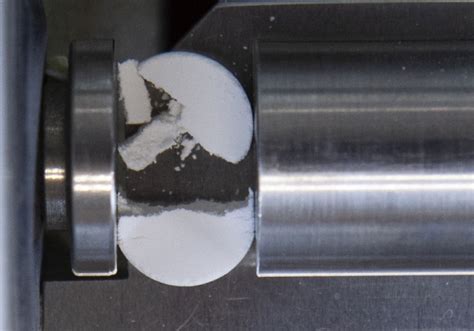

tensile strength vs hardness tablet

In the Pfizer hardness tester, the vertically mounted tablet was squeezed in a device that resembled a pair of pliers. In the Strong Cobb hardness tester, the breaking load was applied through the action of a small hydraulic pump that was first operated manually but was later .One commonly employed test of the ability of tablets to withstand mechanical .Tablet Friability ApparatusFor tablets with a unit mass equal to or less than 650 mg, take a sample of whole tab. ets corresponding to 6.5 g. For tablets with a unit mass of more than 650 .Manufacturing processes such as coating, packaging, and printing can involve considerable stresses, which the tablets must be able to withstand. For these reasons, several tests are .

The system can test for trends in weight, hardness, thickness, diameter/length and width variation in tablets, sending results to a central server, generating IPC data that can be translated to full . Hardness and Friability Test for Tablets. September 30, 2021. Hardness and friability are important physical parameters for a tablet. These parameters ensure the strength and structural integrity of a tablet for . The new USP chapter <1217> in USP 31 NF6 titled “Tablet Breaking Force” highlights a number of essential factors that you must consider when using a tablet hardness tester machine. Let’s look at some of the USP .

One commonly employed test of the ability of tablets to withstand mechanical stresses determines their resistance to chipping and surface abrasion by tumbling them in a rotat-ing .A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet.ERWEKAs hardness testers offer a 100% USP conform solution for every budget and tablet shape. From entry-level manual hardness testing with the TBH 125 to the fully automated, .Proven to be the most advanced, precise, and user-friendly manual tablet hardness tester, the MT50 with high-precision Dr. Schleuniger® technology is an all-time favorite in both laboratories and compression rooms.

Under these circumstances, it is normally not necessary to include these attributes in the specification. If the characteristics of hardness and friability have a critical impact on drug product quality (e.g., chewable tablets), .Hardness Testing. A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. SOTAX tablet .Hardness Testing. A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. SOTAX tablet hardness testers with precision Dr. Schleuniger® measuring technology, standard-setting user friendliness .

Their “Monsanto Hardness Tester” measured the resistance of tablets to crushing, whereby the tablets were subjected manually to radial stress using a spring-loaded screw. . or a constant platen movement of 3.5 mm/s or less for strain controlled testing. The USP requires that the optimum stress or strain rate to ensure tensile failure .tablet sample after tumbling, the sample fails the test. If the results are difficult to interpret or if the weight loss is greater than the target value, the test should be repeated twice and the mean of the three tests determined. A ( U SP 1 -Au g - 2 0 2 3 ) weight . .

200 Tablet Hardness Tester Operator’s Manual 2 Introduction Conventions Used in this Manual 14 The 200 is designed to help you easily check the critical physical parameters specified in the USP General Chapters <711> Dissolution and <724> Drug Release. The 200 tests and documents the parameters of the following variables:

Pharmaceutical Testing Hardness T 50 Background: Hardness Testing Together with friability, hardness (or breaking force) is a defining physical characteristic for a tablet. High hardness values may . Chapters Ph. Eur. 2.9.8 Resistance to Crushingof Tablets and USP Chapter <1217> Tablet Breaking Force describestandardised methods for the .

Should you have any questions about this General Chapter, please contact William E. Brown (301-816-8380 or [email protected]). For any questions about the PDG and its processes, please see Pharmacopeial Harmonization Group or .

Hardness testing after brief exposure (30 seconds) to a small quantity (for example, 1 mL) of human simulated saliva may provide data that could be used to support the hardness specification.All Pharma Test tablet hardness testing instruments are fully compliant to the requirements of the current USP Pharmacopeia. The PTB 311E/511E/311E-800 offers a built-in calibration and validation program for the hardness test station. To validate the hardness test station the PT-MT3 magnetic tablet or different certified weights are used. The units of measurement of tablet hardness are Kilogram (kg), Newton (N), Kilopond (kp), Pound (lb), and Strong-Cobb (SC). . The USP dissolution test in the monograph is related to the Bioavailability and Bioequivalence study only when closely allied with a sound regulatory determination. Without this association, the dissolution test should .The new standard for Performance Verification Testing is now official as of May 1, 2023. USP General Chapter < 711> Dissolution revisions are now official and the new USP DPVS – Prednisone is the official Reference Standard

All Pharma Test tablet hardness testing instruments are fully compliant to the requirements of the current USP Pharmacopeia. PT-MT3 for dynamic hardness calibration The PTB111E / 111E-500 / 111E-800 offers a built-in calibration and validation program for the hardness test station.

tablet hardness tester price

Charles Ischi AG - Testing Technology is offering fully compliant testing equipment meeting with the revised United States Pharmacopoeia USP-1217 tablet breaking force standards with its automatic QC and IPC tablet testing system Kraemer UTS4.1 and its licensed operation Software.The dissolution test in a USP drug product monograph helps evaluate the performance of a drug product (article) and indicates when the drug product performs in a substandard fashion. Although passing the test does not definitively demonstrate bioavailability of the sample or bioequivalence to other products, failure is a cause for concern. .

Comparison of different USP dissolution apparatuses. Various factors can affect the dissolution of a drug; they are classified under three categories as follows: . quality control test for tablets slideshare, quality control tests for capsules, .From standard tablet hardness tests to tensile strength and three-point flexure testing, the MT50 allows to perform different test types in full compliance with USP <1217> "Tablet Breaking Force", Ph.Eur. 2.9.8 "Resistance to Crushing . hardness and/or friability testing as an in-process control (see. section 2.3). Under these circumstances, it is normally not necessary. to include these attributes in the specification. If theHardness Testing Considerations The following sample characteristics should be consider prior to selecting the hardness testing method to use: • Material • Sample Size • Thickness • Scale • Shape of sample, round, cylindrical, flat, irregular • Gage R & R Material The type of material and expected hardness will determine test method.

USP 35 General Information / 〈1216〉 Tablet Friability867 . filled product labeled as sterile must use a system of risk HEPA filter evaluation and testing, as well as routine particu- . take a sample of whole tablets corresponding as near asThe breaking force of tablets is commonly called hardness possible to 6.5 g. For tablets with a .Replacing the heavy metals attribute was considered unnecessary because (a) the source water specifications (found in the NPDWR) for individual Heavy metals were tighter than the approximate limit of detection of the Heavy metals test for USP XXII Water for Injection and Purified Water (approximately 0.1 ppm), (b) contemporary water system .The hardness test for tablets is governed by multiple regulatory bodies, including the U.S. Pharmacopeia (USP), the European Pharmacopeia (EP), and other national and international organizations. They specify the standard procedures, acceptable ranges, and monitoring frequencies for hardness testing.

Tablet Hardness Testing Instruments Tablet hardness testing is used to test the breaking point and structural integrity of a tablet prior to storage, transportation, and handling before usage. All Pharma Test tablet hardness testing instruments meet the latest requirements of the USP and EP Pharmacopeia.What is Hardness Test and Why it so important? Tablet Hardness Testing is also known as the “ Crushing Strength Test “. Tablets must have a specific level of strength or hardness in order to withstand mechanical shocks during manufacturing, packaging, and shipping. The parallel to friability test, tablets hardness, is also tested to know the strength of tablets which is more important for drugs to withstand throw-out their lifecycle. However, hardness is not only a parameter for tablet strength. . Note: Friability Apparatus shall comply with USP <1216>, EP<2.9.7>, and other pharmacopeias. Friability .

ERWEKAs hardness testers offer a 100% USP conform solution for every budget and tablet shape. From entry-level manual hardness testing with the TBH 125 to the fully automated, high-volume tester MultiCheck 6 with OblongNavigator for alignment of almost any tablet shape, ERWEKA has your requirements covered.

USP <1217> Max. Tablet Diameter: 30 mm. Force Range: 0-200 N (+/- 0.04 N) Statistics Reporting: No. Batch Testing: No. Portable: Yes. Unit Dimensions (w x d x h): . this tester offers easy and convenient tablet hardness testing in busy production environments. Cat No: 7802. Pharmacopoeial Compliance: Ph. Eur. 2.9.8. USP <1217> Max. Tablet .

Perspiration Color Fastness Tester commercial

web24 de mai. de 2022 · Por: redação Fonte: Por Portal do Zacarias Reproducão Uma mulher de 20 anos morreu ao ser imprensada por um ônibus contra a grade de uma das plataformas de embarque do terminal .

usp hardness test|tablet hardness tester price